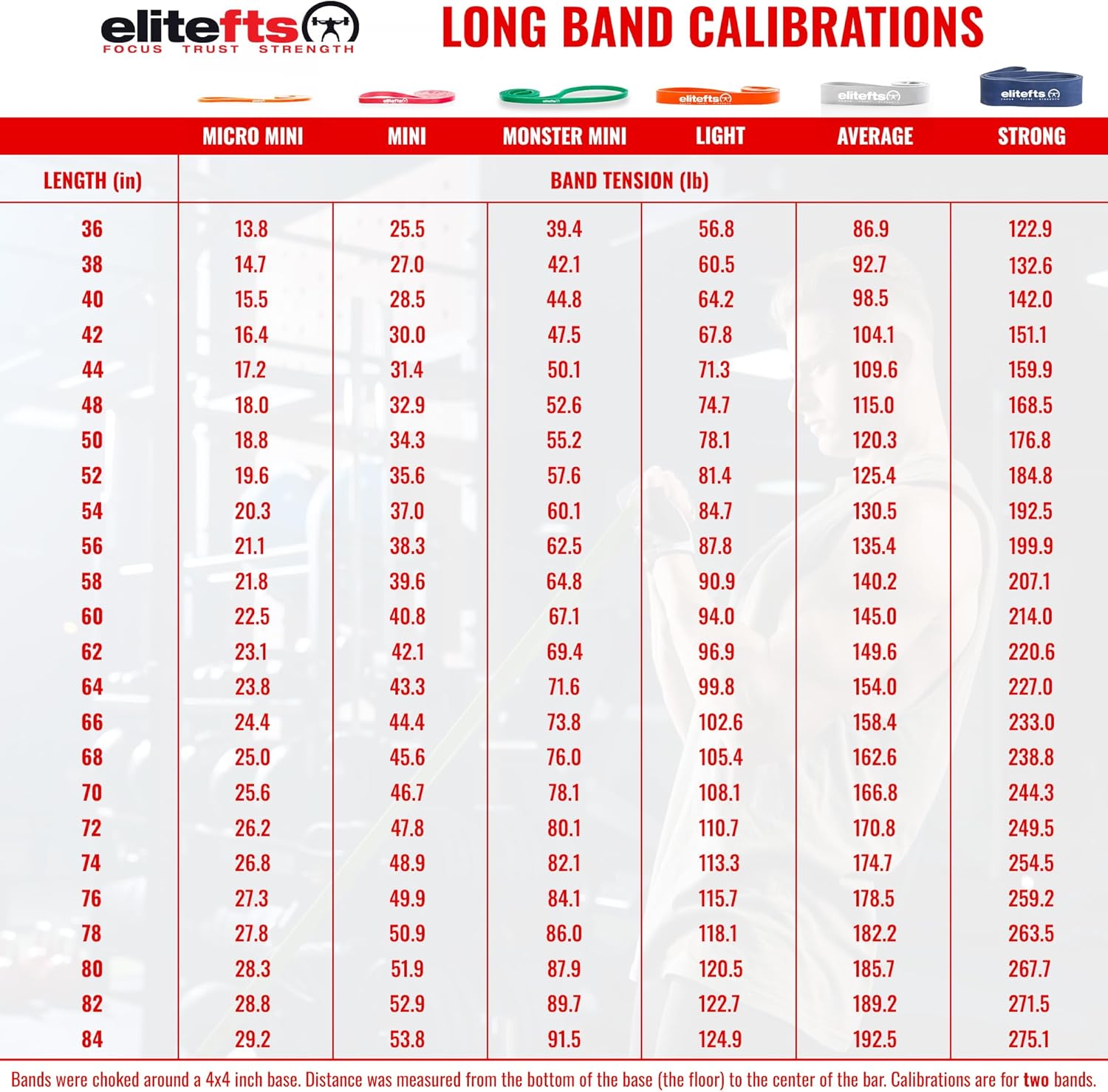

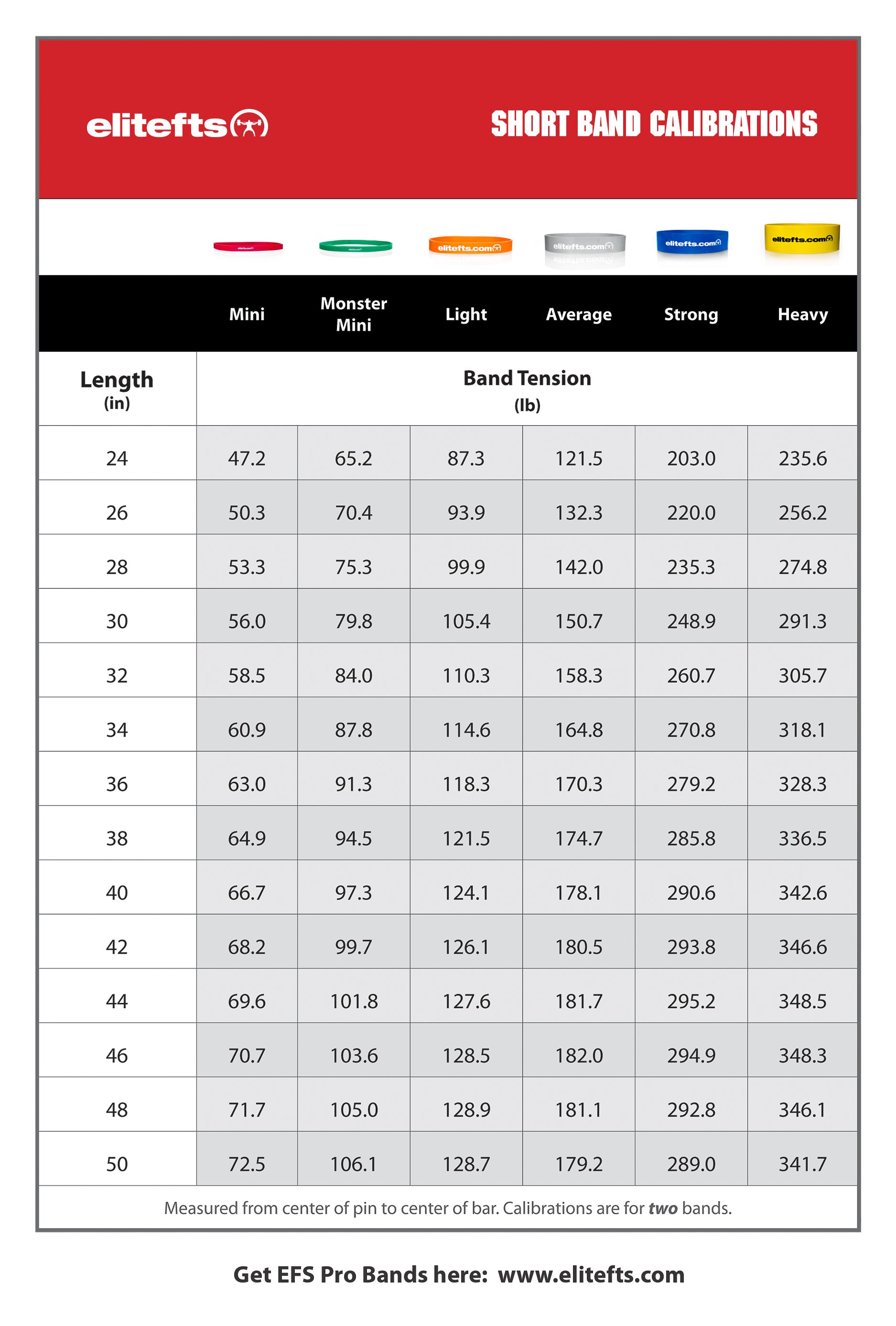

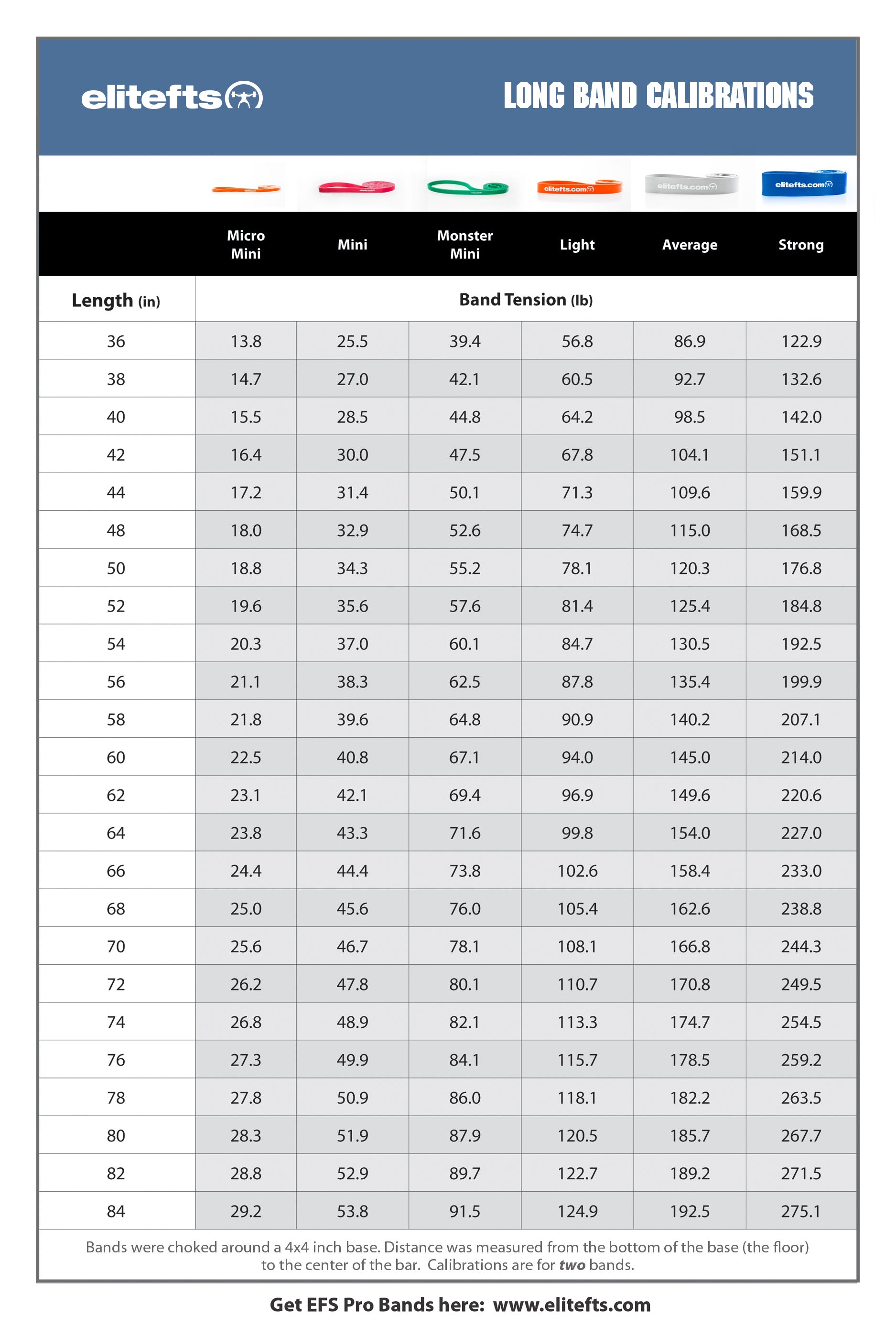

For the 20 years elitefts has been in business, the one question I’ve been asked the most is: Why does your stuff cost more than X company (They are always referring to the cheap places. Not to the companies that make comparably priced, quality equipment). I set out to sell products that can be used by the strongest athletes in the world. And I will always continue to do that. If you build and stock for the strongest, you cover every other user too. But this isn’t easy or cheap to do. One example is our band deadlift platform. I know it works fine as long as the band tension is under 600 pounds. It needs to handle twice that and it’s become a huge pain in the ass. Another example is our SS Yoke Bar. We wanted it to handle 900 pounds and be able to drop it from the j cups to the safeties and not have it break. THAT was a pain in the ass to accomplish. I can go on and on. In this market, most stuff is made with the normal user in mind (someone who squats under 400 for example). It will be great for well over 90% of the market... until someone like Joe Sullivan walks in. Since most places he trains make sure the equipment is inspected and on point, he has no reason to think otherwise. He and all lifters like him should take notice and double inspect what they use when it’s not their normal gym. NEVER ASSUME! Trust me; I know that people in this industry buy cheap most the time. While this is kind of funny to watch, notice Joe said he jacked his knee up. I wish him the best but he won’t know the extent of this issue for a bit.

If the bar ain't bending, you're just pretending... not really!

For the 20 years elitefts has been in business, the one question I’ve been asked the most is: Why does your stuff cost more than X company (They are always referring to the cheap places. Not to the companies that make comparably priced, quality equipment). I set out to sell products that can be used by the strongest athletes in the world. And I will always continue to do that. If you build and stock for the strongest, you cover every other user too. But this isn’t easy or cheap to do. One example is our band deadlift platform. I know it works fine as long as the band tension is under 600 pounds. It needs to handle twice that and it’s become a huge pain in the ass. Another example is our SS Yoke Bar. We wanted it to handle 900 pounds and be able to drop it from the j cups to the safeties and not have it break. THAT was a pain in the ass to accomplish. I can go on and on. In this market, most stuff is made with the normal user in mind (someone who squats under 400 for example). It will be great for well over 90% of the market... until someone like Joe Sullivan walks in. Since most places he trains make sure the equipment is inspected and on point, he has no reason to think otherwise. He and all lifters like him should take notice and double inspect what they use when it’s not their normal gym. NEVER ASSUME! Trust me; I know that people in this industry buy cheap most the time. While this is kind of funny to watch, notice Joe said he jacked his knee up. I wish him the best but he won’t know the extent of this issue for a bit.

EliteFTS Table Talk— Where strength meets truth. Hosted byDave Tate, Table Talk cuts through the noise to bring raw, unfiltered conversations about training, coaching, business, and life under the bar. No fluff. No hype. Just decades of experience — shared to make you stronger in and out of the gym.

Join the Crew!

Support us and access premium content monthly!